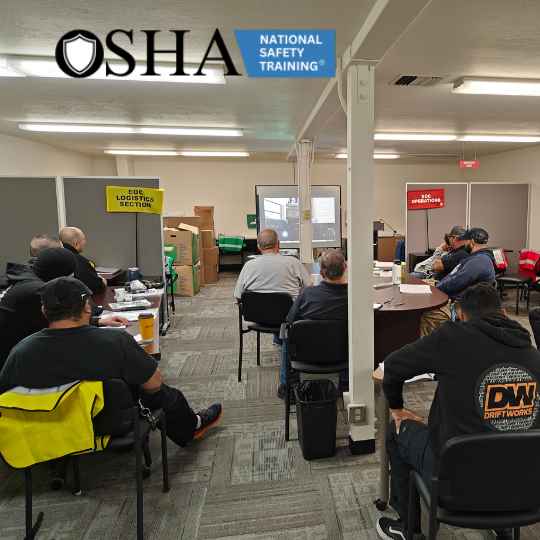

On Site MEWP Safety Training and Certification

Best Priced & Value Guranteed!

Train The Trainer Certification

The Importance of 3rd Party On-Site MEWP Safety Training:

Third-party on-site MEWP (Mobile Elevating Work Platform) safety training is crucial for businesses aiming to maintain a safe and efficient workplace. This specialized training significantly enhances safety standards, ensuring that workers operate MEWPs with the utmost proficiency and caution. By bringing in expert trainers, companies can ensure compliance with safety regulations and avoid potential legal issues.

Such training is not just a regulatory necessity; it’s a strategic investment in workforce competency. Well-trained employees using MEWPs are less likely to be involved in accidents, leading to a safer work environment and increased productivity. Opting for external experts for MEWP safety training demonstrates a company’s commitment to the highest safety standards and its dedication to equipping its workforce with the skills needed for safe and effective MEWP operation.

Understanding the New ANSI Standards for MEWP: A Guide for Employers and Operators

The American National Standards Institute (ANSI) introduced significant updates to the National Safety Standards for Aerial Work Platforms in 2019, with ANSI A92.22 and A92.24. These changes have raised questions among employers and training providers about the implications for internal training programs and compliance. This article aims to clarify these new standards, focusing on their impact on employer responsibilities and the updated Mobile Elevated Work Platforms (MEWPs) training requirements.

Section 1: Overview of the ANSI/SAIA A92 Updates

Subsection 1.1: The Intent Behind the Changes

The ANSI/SAIA revisions aimed to consolidate requirements for similar MEWP types and applications, replacing the previous A92.3, A92.5, A92.6, and A92.8 standards. Notably, A92.2 Vehicle Mounted Platforms remain unchanged.

Subsection 1.2: New Terminology and Standards

A key change is the introduction of new terminology. MEWPs replace all previous ANSI classifications. The two pivotal standards are A92.22 (Safe Use of MEWPs) and A92.24 (Training Requirements and Responsibilities for MEWPs).

Section 2: Implementation Timeline

Subsection 2.1: Effective Date of the New Standards

Initially set for December 1, 2019, the effective date for these standards was postponed to June 1, 2020, due to emerging issues.

Section 3: Classification Changes in MEWPs

Subsection 3.1: New Equipment Categories

Under the new standards, equipment is categorized into three Types, each with two Groups:

– Type 1: Movement only with the platform stowed.

– Type 2: Movement with the platform elevated, operated from chassis controls.

– Type 3: Movement with the platform elevated, operated from platform controls.

Subsection 3.2: Group Classifications

Each Type has Group A (platform does not extend beyond the tipping axis) and Group B (platform extends beyond the tipping axis). Notably, Type 3 MEWPs, including scissor lifts (Group A) and boom lifts (Group B), are most common in workplaces.

The ANSI A92.22 and A92.24 standards mark a significant shift in the safety and training landscape for MEWPs. Understanding these changes is crucial for employers and training providers to ensure compliance and maintain high safety standards. By adapting to these new requirements, the industry can continue to operate MEWPs safely and efficiently.

MEWP Types and Groups

- Type 1, Group A

- Type 1, Group B

- Type 1, Group A

- Type 2, Group B

- Type 3, Group A

- Type 3, Group B

One Day Onsite Mechanical Elevating Work Platform (MEWP) Training Agenda

Duration: Between 4-6 hours depending on type of training.

Session 1: Introduction to MEWP Lifts and Safety Principles

This session begins with a warm welcome and participant introductions, creating a conducive learning atmosphere. An overview of the training agenda is presented, highlighting the key topics and goals. The session emphasizes the importance of on-site MEWP lift training in enhancing workplace safety and reducing accidents. Participants are encouraged to actively participate, fostering a culture of safety and responsibility in their work environment.

Session 2: Understanding Different MEWP Lifts and Their Components

Participants explore various types of MEWP lifts and their applications in different settings. This session provides an in-depth look at the components and controls of lifts, emphasizing safe and effective usage. The focus is on selecting the appropriate lift for specific tasks and mastering its operation to ensure safety and efficiency in the workplace.

Session 3: Pre-Operational Inspections and Stability of MEWP Lifts

The importance of pre-operational checks for ensuring the safety and functionality of MEWP lifts is highlighted. Participants learn to inspect components like tires, controls, and safety devices, understanding the significance of tagging out defective equipment. This session underlines proactive safety measures and regulatory compliance for safe MEWP operations.

Session 4: Hands-On MEWP Lift Operation

Participants gain practical experience in operating MEWP lifts within a controlled setting. This hands-on training focuses on maneuvering skills, precise steering, and basic load handling techniques. The session aims to build confidence and proficiency in operating MEWP lifts safely in real-world scenarios.

Session 5: Hazard Recognition and Practical Evaluation

This session emphasizes identifying potential hazards and strategies to prevent common accidents with MEWP lifts. Participants engage in a practical evaluation to apply their skills in realistic situations, assessing their ability to operate safely and efficiently. This evaluation is crucial for understanding their operational strengths and areas for improvement.

Session 6: Certification and Training Recap

Participants who successfully complete the training receive certificates of achievement in MEWP lift operation and safety. The session concludes with a review of key safety points and a Q&A segment, allowing for feedback and clarification. This final session ensures participants leave with a comprehensive understanding of MEWP lift safety and operation, ready to contribute to a safer workplace.